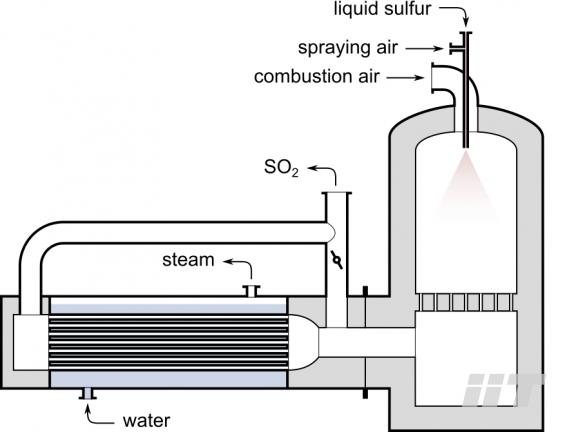

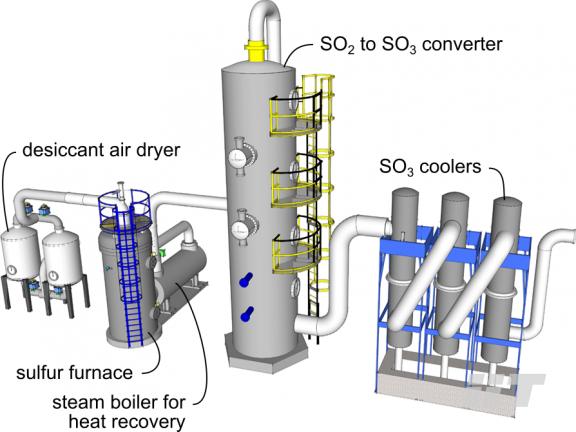

Our sulfur furnaces are equipped with a preheating system that heats the incoming combustion air above sulfur self-ignition temperature (243°C) during the plant startup, in order to avoid any possible accumulation and pooling of non-burned sulfur, common cause of operational and maintenance issues. Once sulfur ignites, the combustion air preheating is switched off. The preheating system can be retrofitted to upgrade any existing burner.

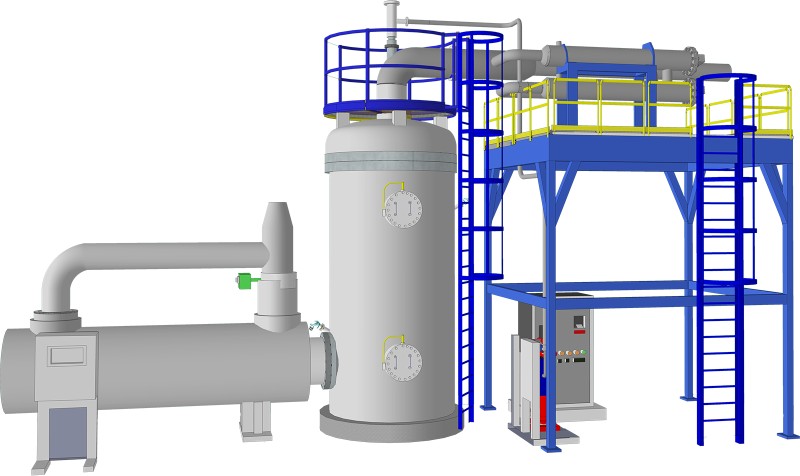

The heat developed by sulfur combustion can be recovered either directly in steam boilers or indirectly by heat exchange with an intermediate fluid, like ambient air. The intermediate fluid can be then used in other equipment, as well as to generate steam, hot water or chilled water. IIT has both technologies available.

The steam boiler is directly connected with the sulfur burner without any interconnecting piping, allowing the maximum heat recovery efficiency. Every surface of the boiler in touch with the gas is coated with refractory material, exept for heat exchanging tubes, which are subjected to temperatures only slightly higher than that of the water in which they are immersed.

A preheating device allows to bring the boiler temperature above the acid condensation point before the startup. The whole cladding of the boilers works therefore at suitable temperatures for carbon steel. The boiler is automatically controlled in order to adjusts the temperature of the gas stream sent to the SO2 converter.